Key Takeaways:

- If your hospital wants blue wrap (sterilization wrap) recycling, the best way to ensure its future is to actively seek products made from recycled blue wrap.

- The current recycling landscape has far too much plastic waste supply and not enough demand for plastic waste as a commodity to incentivize blue wrap recycling (due in large part to China’s banning recyclable imports).

- Recycling programs are relatively easy to set up, but the true challenges (or larger barriers) arise when the plastic leaves the hospital.

- Blue wrap recycling is a huge circular economy opportunity that could prevent massive amounts of waste from going to rapidly depleting landfills.

- There are several products made from recycled blue wrap, and designed to replace single-use plastic products, that are available now for use in healthcare.

- Blue wrap can be recycled, upcycled, or incinerated to create energy. All of which have pros and cons.

This guide will serve as a work in progress and will be updated and improved as time goes on. Disclaimer: I co-own and manage Circular Blu, which is mentioned as a solution.

Introduction:

Anyone who has worked with blue wrap (sterilization wrap) has seen the struggle first hand. Thousands of lbs of this plastic fabric pass through your hospital only to be disposed of. Despite the best efforts of OR nurse champions and other engaged staff members, the material often ends up in a landfill. This guide will provide you with all the resources and tactics you need to navigate this issue with acumen and create a circular economy around blue wrap at your hospital.

For anyone who is not familiar with sterilization wrap, which is commonly referred to as “blue wrap”, Halyard Health describes it as:

Sterilization wrap is a three-layer laminate composed of a layer of meltblown polypropylene bonded on both surfaces with a layer of spunbonded polypropylene. The sheets of sterilization wrap are square or rectangular fabric produced using a polypropylene three-layer SMS (spunbond-meltblown-spunbond) process.

The wrap is intended to allow sterilization of the enclosed medical device(s) and also to maintain sterility of the enclosed device(s) until opened. Sterilization wrap works by allowing the sterilizing agent (e.g., steam, ethylene oxide, hydrogen peroxide gas plasma, etc.) to penetrate and then providing a barrier to maintain sterility of the wrapped surgical instruments.

Description of the Problem

The magnitude of this issue is greater than most people realize. Potentially hundreds of millions of lbs of sterilization wrap are consumed and discarded annually in the US. Considering that it is a clean homogenous waste stream that is 100% polypropylene (plastic #5), one would think that recyclers would be highly engaged in collecting it. The truth of the matter is that there are several economic, logistical, and infrastructure related obstacles that must be overcome in order to recycle it successfully.

Obstacles to Recycling

- Blue wrap is too voluminous to be economically freighted without being baled, and most hospitals don’t have space or room in the budget for a baling machine.

- More and more waste haulers are discontinuing blue wrap pick-ups due to difficulties in the recycling market that are likely stemming from China’s National Sword.

- Many hospitals don’t have the space to store used blue wrap to aggregate minimum viable load requirements.

- OR staff needs to be trained to segregate blue wrap and remove any from the OR pre-incision, to eliminate the possibility of contamination.

- There is a lack of domestic recycling infrastructure.

- There is a national shortage of truck drivers, driving the price of hauling up.

- Low oil prices have caused the prices of virgin plastic resin to be lowered. The price of recycled plastic resin is correlated to that of virgin resin, causing a devaluing of recycled resin.

Opportunities and Benefits of Recycling Medical Plastics

- Creating a recycling program can lead to a reduction in MSW tipping fees.

- Patients are becoming increasingly concerned with environmental stewardship when choosing a hospital and providing feedback on hospitals.

- Recycling programs are vital to environmental recognition awards through institutions such as Practice Greenhealth.

- Outwardly promoting circular economy items and products made from a hospital’s own waste stream will improve outward perception.

- Hospital staff and administration can feel pride in doing what is right for the environment, instead of feeling ashamed at how much waste is produced.

Future Projections of Waste Climate and Landfills

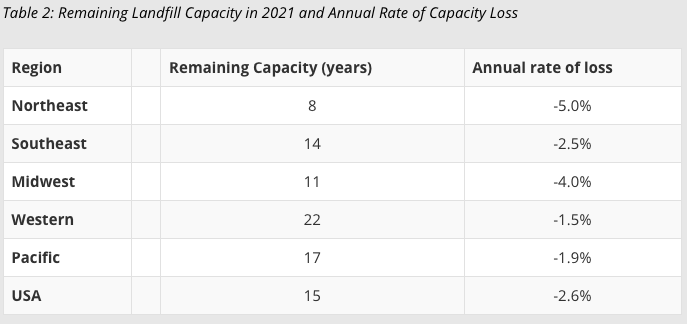

There will come a time when it becomes more economical to recycle blue wrap than landfill it. Plastic is a non-renewable resource and contains value as a commodity, and the price of landfilling is projected to increase considerably over the next decade. In fact, many landfills are going to reach capacity far sooner than most people realize.

The following information was taken from an article by the Solid Waste Environmental Excellence Protocol (SWEEP):

“Based on data collected by Waste Business Journal, over the next five years, total landfill capacity in the U.S. is forecast to decrease by more than 15%. This means that by 2021 only 15 years of landfill capacity will remain. However, in some regions, it could be only half that.”

Another SWEEP article goes on to estimate the increase in landfilling costs based on these future projections:

“According to data compiled through Waste Business Journal’s direct survey of landfill managers, the national average cost per ton of landfilled waste in 2017 was $50.30 per ton, which is forecast to rise to $51.19 by the end of 2018 and projected to climb even higher through 2021.”

“Nationally, the MSW tipping fee, which includes both landfill and incineration disposal, is projected to rise another 6 percent to $53.53 per ton by 2021. As shown in Table 1 below, there is a fairly wide range of price growth across the US, with waste costs in the Pacific region increasing more than twice as fast as those in the Southeast.”

This data on landfill capacity loss and the projected increase in tipping fees highlight the importance of recycling medical plastics. The above data was compiled before China’s National Sword, which has increased the number of recyclables entering landfill thus expediting the timeline of these estimates. The cost of landfilling may soon become a much more compelling financial imperative to recycle medical plastics.

Producers of Single-Use Plastic Products in Healthcare

Part of the transition to a circular economy will involve producers/suppliers of these single-use products taking responsibility (at least in part) for the waste that their products produce. This is a concept known as Extended Producer Responsibility, and I believe that it will become a sales imperative as we move towards a more waste-free future. Hospitals should put emphasis on the need for suppliers that they contract with to provide post-use services for the waste that their products create. Conversely, suppliers will be able to sell more products if they have a network in place for handling the waste these products produce, as it will alleviate the cognitive dissonance and mental burden associated with making purchases that create massive amounts of waste. If you want a recycling program for your blue wrap, be sure to tell your supplier that it is important to you!

Many other single-use polypropylene products may be able to be included in your hospital’s blue wrap recycling program, pending approval by Circular Blu.

Designing and Executing a Blue Wrap Recycling Program

Much of the success of a blue wrap recycling program depends upon the Operating Room staff. However, it requires a commitment (or “buy-in”) from your upper management, EVS manager, sustainability manager, and OR staff, and it is essential to have a dedicated nurse champion. It can also be very helpful to have a representative from procurement or supply chain, your sterilization wrap corporate account manager, and even an executive sponsor. Here is a great resource on recycling in the OR by Practice Greenhealth.

Before Moving Forwards with a Recycling Plan! Read the Following:

Do not put a significant amount of work into planning a recycling plan if you don’t have a waste hauler who will pick up blue wrap and ensure that it is actually going to be recycled. Usually, this important facet is outside of a hospital’s scope of operations but Circular Blu is an expert in the area and can help!

Staff cooperation and Training

It is essential that involved staff members are briefed and act according to safe blue wrap collection practices. It is a very simple process but it must be ingrained in the minds of OR and EVS staff.

Most hospitals undergo diversion of recyclables during surgical set-up. At this time, surgical kits are unpacked, new supplies are opened and lots of recyclable packaging materials must be disposed of. Staff members should have an understanding of what materials are recyclable and where to put them. Hospital staff MUST tie off the bag and remove it from the room before the patient enters. When recyclables are removed from the OR before the patient enters the room, it can be referred to as Pre-Incision waste, indicating that it will be free of bio-contamination.

Signage

Creating signage can be a very helpful way of notifying hospital staff of the correct receptacle for various recyclables. Signage also acts as a visible reminder to recycle. Often, your sterilization wrap supplier may be able to provide signage.

Determining Logistics

There are many considerations when designing a blue wrap recycling program, many of which will be unique to your hospital. Typically, hospitals will have little room to store blue wrap waste as it accumulates. When determining logistics, one important consideration is to determine the pickup frequency.

Determining Pickup Frequency

Blue wrap waste pickup frequency is a function of the amount of wrap consumed and the available room for storage. Generally, 80% of blue wrap consumed can be collected without contamination, while the other 20% ends up in RMW (Regulated Medical Waste). Pickup frequency can be determined by conducting a blue wrap volume analysis and using said analysis to extrapolate the time it will take for storage space to run out. Hospitals with highly restrictive storage availability may require frequent pickups, and consequently, must contract a hauler that visits the hospital frequently. If your hospital has a baler and/or ample room to store blue wrap, pickup frequency will be much more flexible and can be far less frequent.

Identifying a Hauling Partner

One of the most difficult and essential components of creating a successful blue wrap recycling program at your hospital is to find a hauling partner to collect wrap and send it downstream to recyclers. Recycling Programs are dependent upon having a collection partner that shares similar sustainability values and visits the dock frequently.

Historically there have been companies such as confidential document destroyers, that have provided backhauling solutions for hauling blue wrap. Recently, however, there has been a large provider that has dropped their blue wrap collection service completely. I have also heard reports of a hauling company that claimed that the blue wrap they were collecting was being recycled when in reality they were secretly landfilling it as MSW.

Downstream flow of the collected plastics is the most challenging component of creating a recycling program. Circular Blu and it’s partners have the connections and expertise to creating a long term solution that we ensure is managed so that all recyclable plastic is actually recycled and reprocessed into circular economy products.

If you have any information or questions regarding the downstream flow of medical plastics please comment below or contact us at info@circularblu.com. We may be able to set you up with a logistics partner to fit your specific needs.

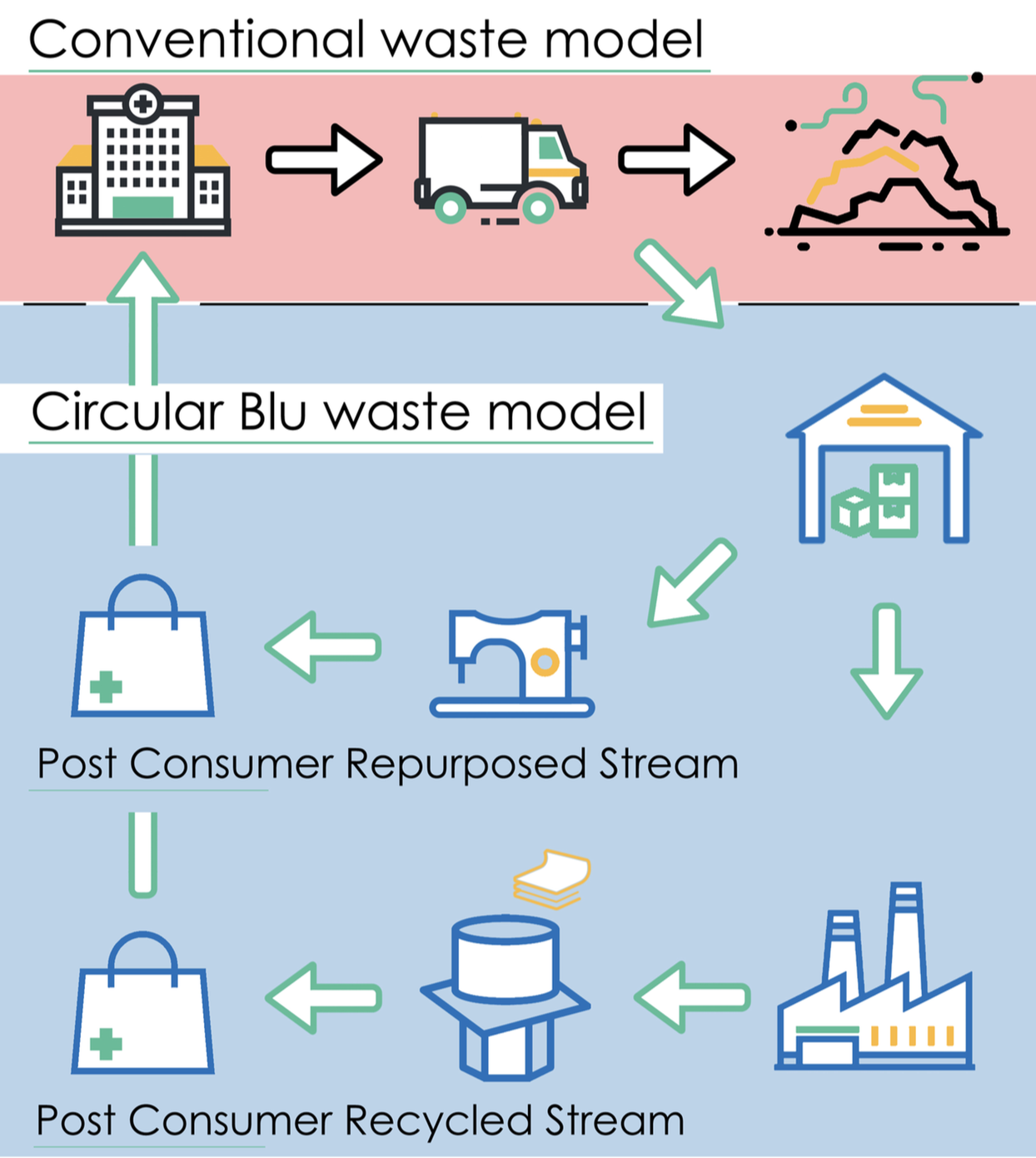

The Blue Wrap Circular Economy

In the blue wrap circular economy (which can include all other medical polypropylene plastics), the blue wrap is collected from hospitals and made into products to be used again in hospitals. Generally, polypropylene can be recycled multiple times without thermal degradation of the plastic, thus allowing for several cycles. Recycled items can enter into the hospital’s polypropylene waste stream, mixing with virgin polypropylene from blue wrap and other sources further minimizing thermal degradation.

If you are a supplier of a single-use, recyclable polypropylene product, please reach out to Circular Blu about creating a recycling program surrounding your product.

Solution 1: Recycling

The Blue Renew Program by Halyard Health

The Blue Renew program is an initiative that has had great success helping nearly 300 hospitals to recycle over 4 million lbs of blue wrap since 2010. The program is only for Halyard Health customers, however, leaving many hospitals excluded. The program operates by engaging with hospital green teams in the OR and providing training and support to ensure best practices in pre-incision wrap segregation. Each program is specifically catered to the needs and obstacles of a given hospital and their logistical and waste circumstances.

The wrap that is collected is sent downstream to recyclers and some of it enters the polypropylene commodities market, while a good amount of it is made into BlueCON resin. BlueCON resin a proprietary plastic blend made from blue wrap by Daniel Constant and Sustainable Solutions LLC, and is licensed by Halyard Health. Several products are being made from BlueCON resin to be sold to the healthcare sector, creating a closed loop model where waste collected from hospitals is collected, turned into a new product, and sold back to hospitals.

Pros and Cons of Recycling Medical Plastics:

Recycling of blue wrap is the solution that can address the largest amount of volume. The largest hurdle (in my opinion), is the current recycling climate. Since China’s National Sword, PCR plastic waste has been devalued by a lack of demand and over-supply. It has become increasingly difficult to find buyers of plastic waste. If hospitals want to recycle their blue wrap, then they need to be the ones who create demand for the recycled blue wrap. Otherwise, the whole initiative will erode and hospitals will be stuck with landfilling.

Pros:

- Recycled blue wrap is far easier to scale than upcycling. The blue wrap can be baled and shipped in freight loads of around 30,000 lbs to be recycled. It will be far easier to address the massive amounts of plastic waste through recycling than through upcycling/repurposing.

- We are now able to create nonwoven fabric out of the recycled blue wrap, allowing us to make recycled reusable tote bags (can be used for patient belonging bags), scrubs, gowns, drapes, and many other exciting products.

- Recycling allows for the creation of rigid product lines, as well as fabric.

- There are decolorization technologies that allow for recycled plastics to be cast into products of various colors.

- By creating demand for products made from the recycled blue wrap, we can avoid the issues stemming from the current over-supply of plastic waste availability.

- Recycling plastic heats the material to a point where it is completely sterilized, removing the stigma of it being made from “medical plastics”.

Cons:

- Recycling consumes more energy than upcycling (but still uses up to 90% less energy than using virgin plastic)

- There is little comparative demand for recycled resins, as compared to the large supply of plastic waste as a result of China’s National Sword.

PCR Products being made from Recycled Medical Plastics:

Made possible through our Partnership with Sustainable Solutions, we are able to offer several products made from BlueCON resin, which is derived from blue wrap collected through Halyard Health’s Blue Renew Program. BlueCON Resin is a polypropylene resin blend made from 80% Post-Consumer Recycled operating room plastics. Here is a comprehensive list of products that are currently being made from Post-consumer recycled medical plastics:

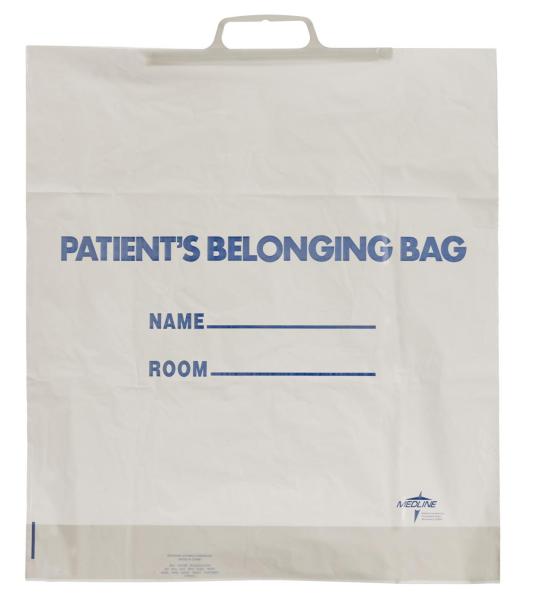

Patient Belonging Bag:

Custom branding available, as well as targeted messaging.

Scrubs:

(Image of scrubs is just a representation, not picture of an actual product, pictures coming soon!)

Pontoon Bedpan:

Fractured Bedpan:

Wash Basin:

15-Gallon Distribution Tote:

7-Gallon Recycling Bin:

(Image of bin above is just a representation, not a picture of actual product)

45-Gallon Recycling Bin:

Impact Metrics of the Blue Wrap Circular Economy Solution (Huge Benefits!)

For the purposes of this example, I will discuss the impact metrics of a typical hospital, who will remain nameless but we will refer to as Hospital A. Hospital A consumes 200,000 patient belonging bags each year.

A case of these bags contains 250 units and weighs 18.3 lbs. Each unit weighs approximately 0.0732lbs.

Hospital A consumes 200k patient belonging bags every year = 14,640 lbs of yearly single-use plastic contributed to landfills. It is very unlikely that the bags would get recycled being a film plastic and only collected in grocery stores in areas without bag bans. To make matters worse, each of those bags is imported from overseas, consuming more resources that often go overlooked. As more and more cities and states ban single-use plastic bags, eventually they will realize the amount of waste is being generated by this type of patient bag and it will likely be banned as well, now that there are much more sustainable alternatives.

On the other hand, that same hospital consumes somewhere around 100,000 lbs of blue wrap in a year. Each tote bag made from blue wrap weighs approximately 0.25 lbs. If the hospital chose to repurpose blue wrap into patient belonging bags, they would be able to divert another 50,000 lbs of plastic waste from landfill.

Overall Statistics from Hospital A replacing all patient experience bags with bags made from recycled blue wrap:

- Total plastic diverted from landfill: 64,640 lbs

- Virgin single-use plastics prevented from being consumed: 14,640 lbs

THIS IS JUST FROM ONE HOSPITAL!! Think of how many hospitals there are in this country.

Metrics of Using Recycled Polypropylene Compared to Virgin Resin

According to an APR study just released in December 2018, it was found that using recycled content polypropylene over virgin has incredible environmental benefits:

- 90% Reduction in Energy Consumption

- 51% reduction in water use when compared to virgin resin

- 77% reduction in contribution to global warming

- 64% reduction in acidification

- 44% reduction in Eutrophication

- 62% reduction in Smog creation

The finding for the study has been adjusted to account for the fact that our sterilization wrap recycling programs utilize trucks that backhaul (already coming and going from hospitals), as well as not including the environmental costs of curbside collection and single-stream sorting.

How many patient experience bags does your hospital consume annually? How much blue wrap does it throw away? What if those products were made from your own waste?

Solution 2: Upcycling

Circular Blu and the World’s Most Sustainable Tote

Audrey Meyers, President and Chief Executive Officer of The Valley Hospital and Valley Health System, and Howard Halverson, Director of Environmental Services holding Circular Blu bags repurposed from blue wrap diverted from landfills as part of their incentive to combat hospital waste and increase their HCAHPS Scores.

The potential for upcycling of blue wrap is greater than any other homogenous waste stream that I have encountered. Blue wrap is made from nonwoven polypropylene, which is the same exact material that reusable tote/shopping bags are made from. Blue wrap can be collected in a perfectly clean state and used directly for tote bag creation using a process known as upcycling. If you compare the amount of blue wrap discarded to the amount of patient experience bags hospitals consume, it paints a very compelling narrative and opportunity for environmental good.

If your hospital is interested in having Circular Blu collect your blue wrap for upcycling, please contact us at info@circularblu.com. Please note that we only collect for upcycling from hospitals in New Hampshire, Vermont, and Massachusetts.

Pros and Cons of Upcycling

Upcycling of blue wrap can lead to the utmost level of environmental attributes. The material is collected, processed, inspected, and sewn into a new product. Every step is completed by hand. There are several pros and cons to this process.

Pros:

- No added energy is expended to change the composition of materials. It doesn’t need to be melted down and reconstituted in any way, just sewn into a new product. For this reason, it is the most sustainable option.

- Since everything must be done by hand, upcycling projects can create jobs.

- Hospitals can create their own grassroots upcycling programs using volunteers who care about reducing plastic waste.

- Upcycling waste is a truly compelling narrative.

Cons:

- Despite proper handling techniques that ensure cleanliness and no contamination, there may still be a stigma attached to the product since it is made from “medical waste”.

- It is very difficult to scale this process to address large unit demand (i.e. patient belonging bags, since many hospitals use over 100,000 units per year).

- Upcycling presents a logistical challenge because if the blue wrap is baled, then it causes the material to become very crinkled, and the products created from the wrap that has been baled are less appealing.

Uses for The World’s Most Sustainable Tote

Upcycled tote bags made from repurposed sterilization wrap have been very successful as promotional items. Customizable branding is available so that hospitals, businesses, and event planners can use these bags to highlight their environmental stewardship. Many conferences are eliminating the use of handout bags and cheap disposable swag due to sustainability concerns, however, these bags are more sustainable than eliminating the conference bag altogether. You may have seen these bags at CleanMed if you have attended any of the past 3-4 years.

Grassroots Upcycling

There have been several innovative and well-constructed initiatives surrounding grassroots collection and repurposing of the blue wrap. Programs such as these are often created, spear-headed and managed by green teams and nurse champions. I commend those who work to save lives while on the clock and work to save the environment while off-duty. Here are a couple of examples of grassroots blue wrap recycling efforts:

Sleeping mats for the homeless at Providence Little Company of Mary Medical Center in Torrance

Handmade blue wrap mats being given to the homeless. (Photo by Steve McCrank, Daily Breeze/SCNG)

Upcycling at UVa Health by Volunteers at M.E.R.C.I. (Medical Equipment Recovery of Clean Inventory)

MERCI has been working for over 25 years to redistribute (without cost) clean usable surplus medical supplies both locally (to educators, researchers, and non-profits) and to medical missions around the world. Their small team of volunteer sewers makes products including several different totes out of some of the blue wrap. These bags are given for free to staff, volunteers, patients and guests to the medical center.

Gail Sullivan of MERCI at UVA Health holding several bags made from repurposed sterilization wrap by volunteers. Hey, that looks like a blue wrap hat as well!

Getting Students Involved:

Lehigh Valley Health Network has taken strides to involve the community in their sterile wrap recycling efforts! It looks like they might even be having fun!

Potential Solution 3: Waste-to-Energy

Plastic waste to energy is a valid solution to reducing waste, but it is often frowned upon for a number of reasons. Essentially what is happening is the plastic gets combusted and the heat energy is transferred into electrical or mechanical energy. A great deal of the total energy in the material is lost and potentially harmful chemicals and greenhouse gases are released into the atmosphere.

There are some processes that convert plastic to diesel fuel using a process known as pyrolysis. Pyrolysis involves heating the plastic to a certain degree to convert it into fuel and then distilling it into diesel. There is also wastewater produced through this method that can contain harmful chemicals. Each ton of fuel oil will use 50 L water, and can contain harmful and polluted elements including pH, SS, petroleum.

Conclusion:

Thank you for reading this post on sterilization wrap recycling and repurposing. I know that it is a huge waste stream and it is one of my biggest missions to find a way to mitigate the harm and waste produced by sterilization wrap. If you have any questions or comments please reach out or comment in the comments section below. If you have anything you would like me to add to this post I would be happy to review your request. Thank you and let’s join together and combat plastic waste!